TSM-09

Sushi Machine / TSM-09

Sushi Ball Machine / TSM-09designed with patented technology Low csot and Easy Operation Model. 1.8 seconds / 1 ball 2,000 balls / 1 hour

UL/NSF /CSA,CE

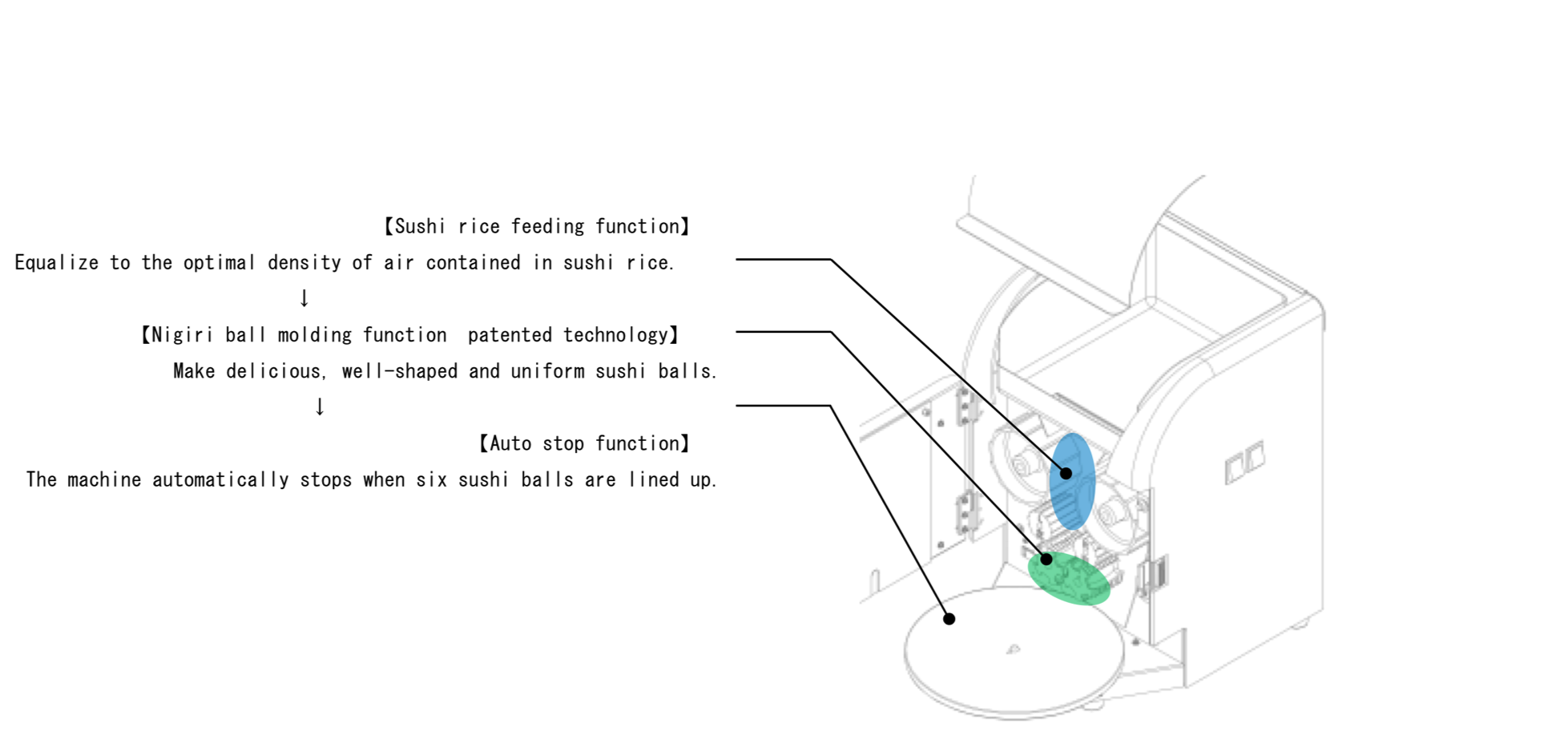

Secret of TOP sushi machine technology

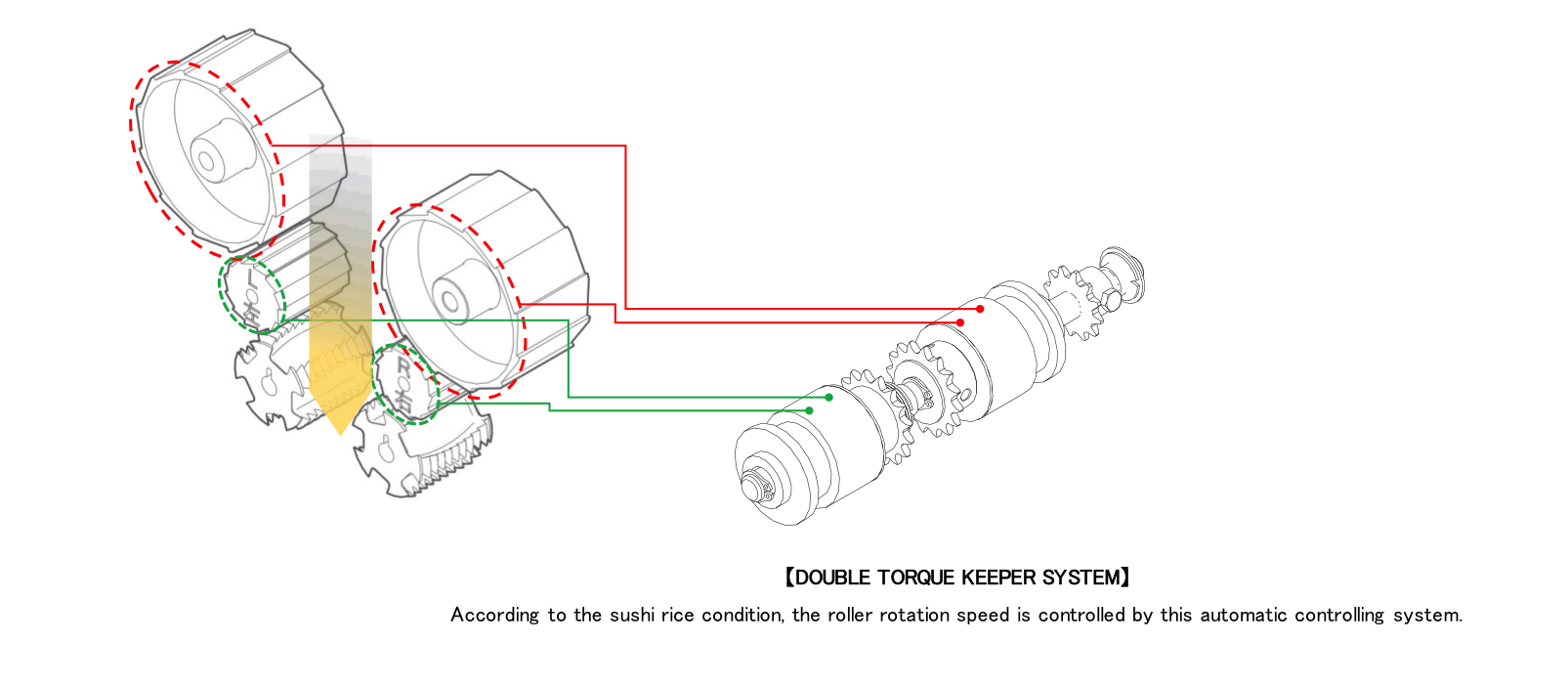

DOUBLE TORQUE KEEPER SYSTEM

Double Torque Keeper System as sushi rice forwarding function for making delicious high quality and uniformed Nigiri rice balls.  【 Double Torque Keeper System as sushi rice forwarding function for making delicious high quality and uniformed Nigiri rice balls 】

【 Double Torque Keeper System as sushi rice forwarding function for making delicious high quality and uniformed Nigiri rice balls 】

- The combination of right and left, upper and middle rollers that are controlled by Double torque Keeper System can detect torque and density of the sushi rice.

- The automatic roller rotation speed controlling can create soft and delicious sushi balls with evenly uniformed shape of Nigiri balls as if the professional sushi chef made.

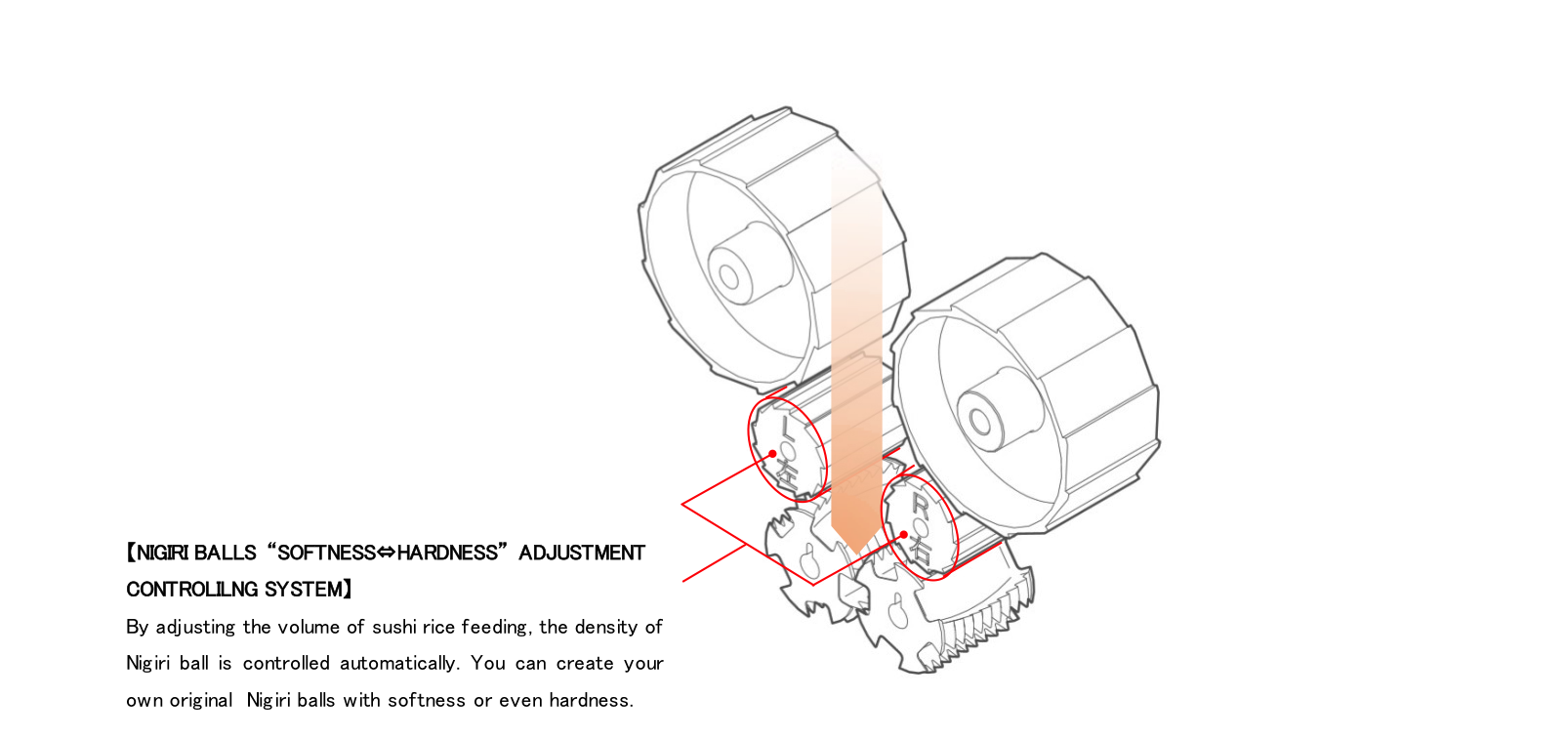

NIGIRI BALLS “SOFTNESS⇔HARDNESS” ADJUSTMENT CONTROLILNG SYSTEM

Nigiri balls “softness⇔hardness” adjusting controlling system for delicious uniformed sushi ball making  【 Nigiri balls “softness⇔hardness” adjusting controlling system for delicious uniformed sushi ball making 】

【 Nigiri balls “softness⇔hardness” adjusting controlling system for delicious uniformed sushi ball making 】

- Nigiri ball softness or hardness can be also adjusted by two of middle rollers that control sushi rice feeding arbitrarily so that you can make your own favorite original Nigiri balls with variety of demands in different culture.

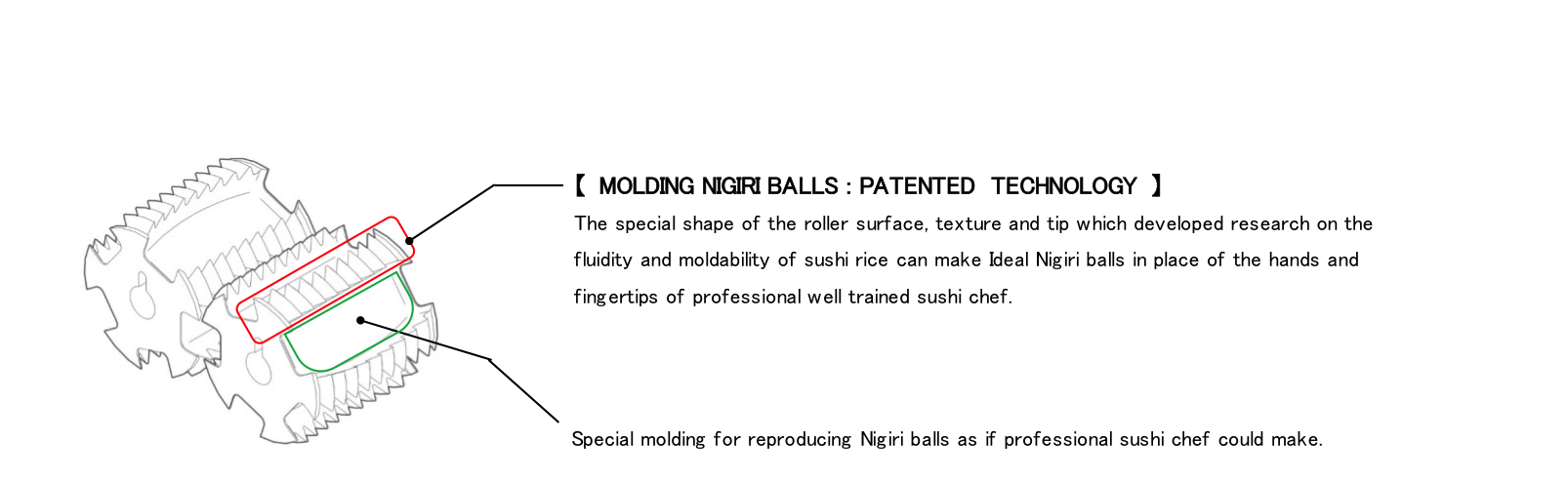

MOLDING NIGIRI BALLS : PATENTED TECHNOLOGY

The special shape of the roller surface, texture and tip which developed research on the fluidity and moldability of sushi rice can make Ideal Nigiri balls in place of the hands and fingertips of professional well trained sushi chef.  【 For delicious uniformed sushi ball making by TOP original special Nigiri molds as patented technology 】

【 For delicious uniformed sushi ball making by TOP original special Nigiri molds as patented technology 】

- The special shape of the roller surface, texture and tip can product the Ideal Nigiri balls constantly, precisely and accurately as if professional well trained sushi chef made. These special molds can reproduce Nigiri balls with the best matching of softness and hardness for sushi lovers.

- The high advanced resin cutting technology is applied for molds cutting and shaping in order to create well-formed Nigiri balls that look beautiful and traditional sushi visuals with pieces of fish or other ingredients.

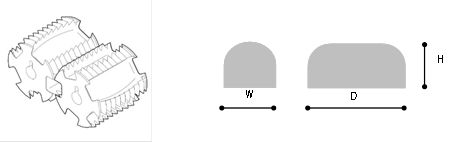

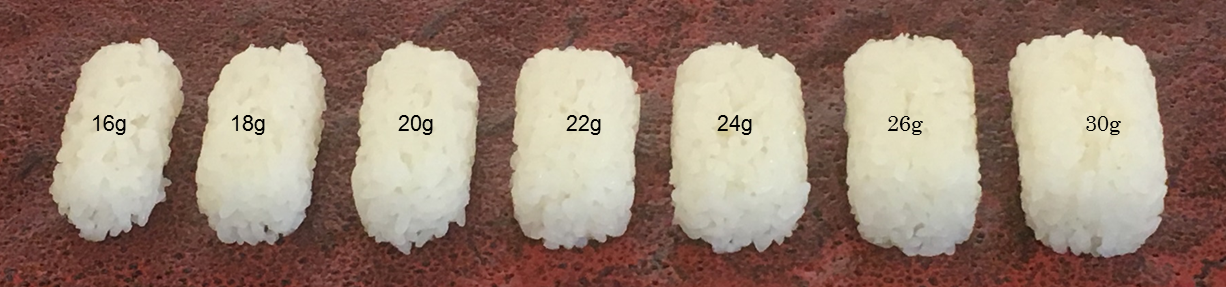

NIGIRI BALL SIZE SELECTIONS

*Above information is for reference only so that please select for your business concept with your country's demands.

Nigiri Ball Volume and Size

| weight | size | useage |

|---|---|---|

| 16g | W24×D53×H20mm | for Nigiri Sushi making |

| 18g | W25×D53×H21mm | for Nigiri Sushi making |

| 20g | W26×D53×H22mm | for Nigiri Sushi making |

| 22g | W27×D53×H23mm | for Nigiri Sushi making |

| 24g | W29×D53×H23mm | for Nigiri Sushi making |

| 26g | W30×D53×H25mm | for Inari Sushi making |

| 30g | W33×D53×H28mm | for Inari Sushi making |

*Size and Volume of balls may get changed with the condition of sushi rice, especially, temperature.  There are two kinds of bale type rollers.

There are two kinds of bale type rollers.

| weight | size | useage |

|---|---|---|

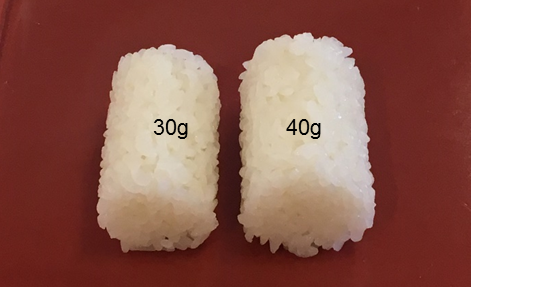

| 30g | W30×D53mm | for lunch box making |

| 40g | W35×D53mm | for lunch box making |

*size and volume may get changed. *it won't be formed as "completed cylinder shaped" *ask more about order made

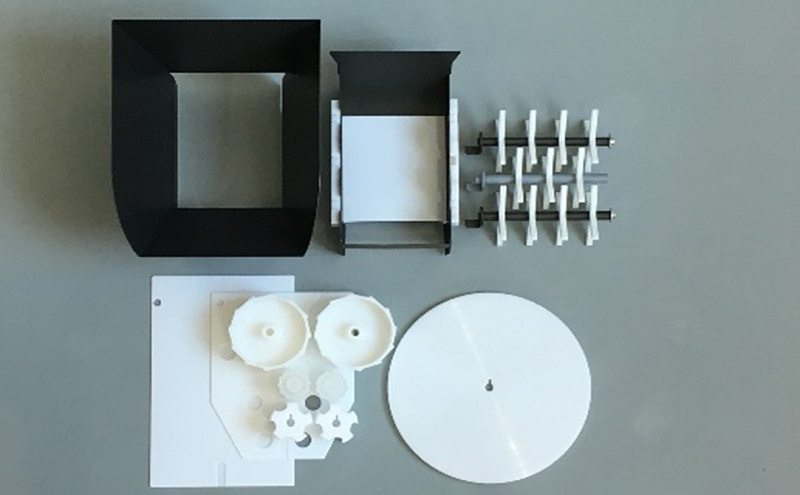

OPERATION ・ CLEANING

DURABILITY ・ LONG LIFE

Japanese manufactured motor with overheated protection guarantees durability and long life use.

Japanese manufactured motor with overheated protection guarantees durability and long life use. The sensor IP67 type is excellent in waterproofness and oil resistance.

The sensor IP67 type is excellent in waterproofness and oil resistance. Main parts are made of stainless steel 304 type for making rust resistant and strength of structure.

Main parts are made of stainless steel 304 type for making rust resistant and strength of structure. Body material is selected for protecting from shock, dirt and heat.

Body material is selected for protecting from shock, dirt and heat.1 minute movie for NIGIRI SUSHI MAKING

Explain how to install TSM-09 parts

Explanation on how to remove TSM-09 parts

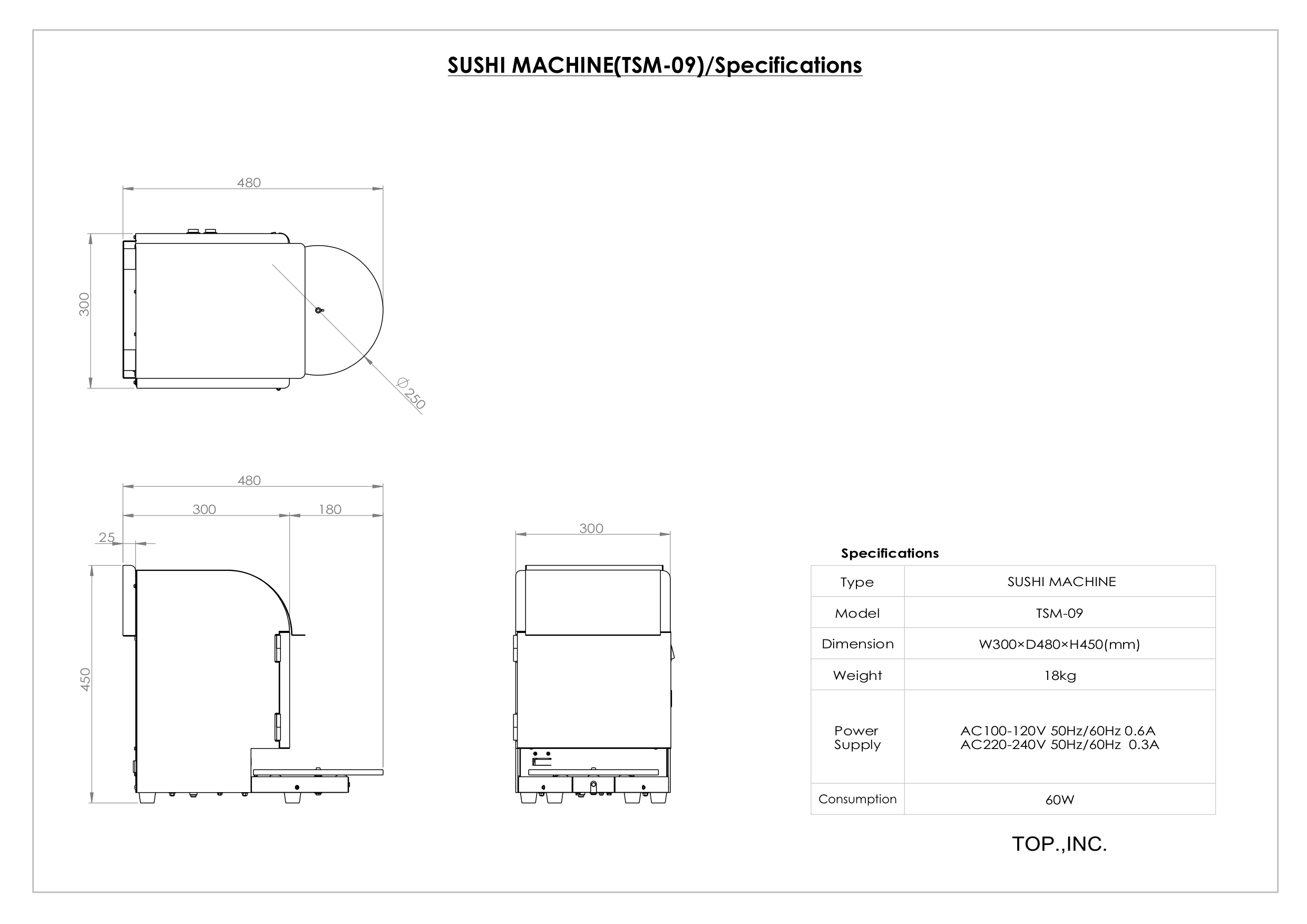

SPECIFICATION

- Product Name

- Sushi Ball Machine

- Type

- TSM-09

- county of use

- TSM-09A; USA, CANADA, 100-120V area

- TSM-09B; Europe, Oceania, Asia, South America, Middle East, Russia, 220-240V area

- standards

- UL/NSF, CSA

- CE, IAPMO(UL/NSF, CSA)

- Production capacity

- 2,600 sushi balls per hour with 16 or 18 or 20 or 22 or 24g ball rollers. ) ( 16,00 sushi balls per hour when the size of one cut is 26.30g )

- Body Dimensions

- W30 x D48 x H59cm

- Body Weight

- 18kg

- Power Supply

- TSM-09 TypeA : 115V

- TSM-09 TypeB : 220-240V

- Power Consumption

- 60W

- Sushi rice Capacity

- 3kg

- option

- sushi ball roller; 16,18,20,22,24,26,30g tawara roller; 25,30g/dd>