TSM-900RS-CK1

2019年1月14日

Last updated :

2019年4月2日

株式会社トップ

株式会社トップ

巻寿司マシン/TSM-900RS-CK1

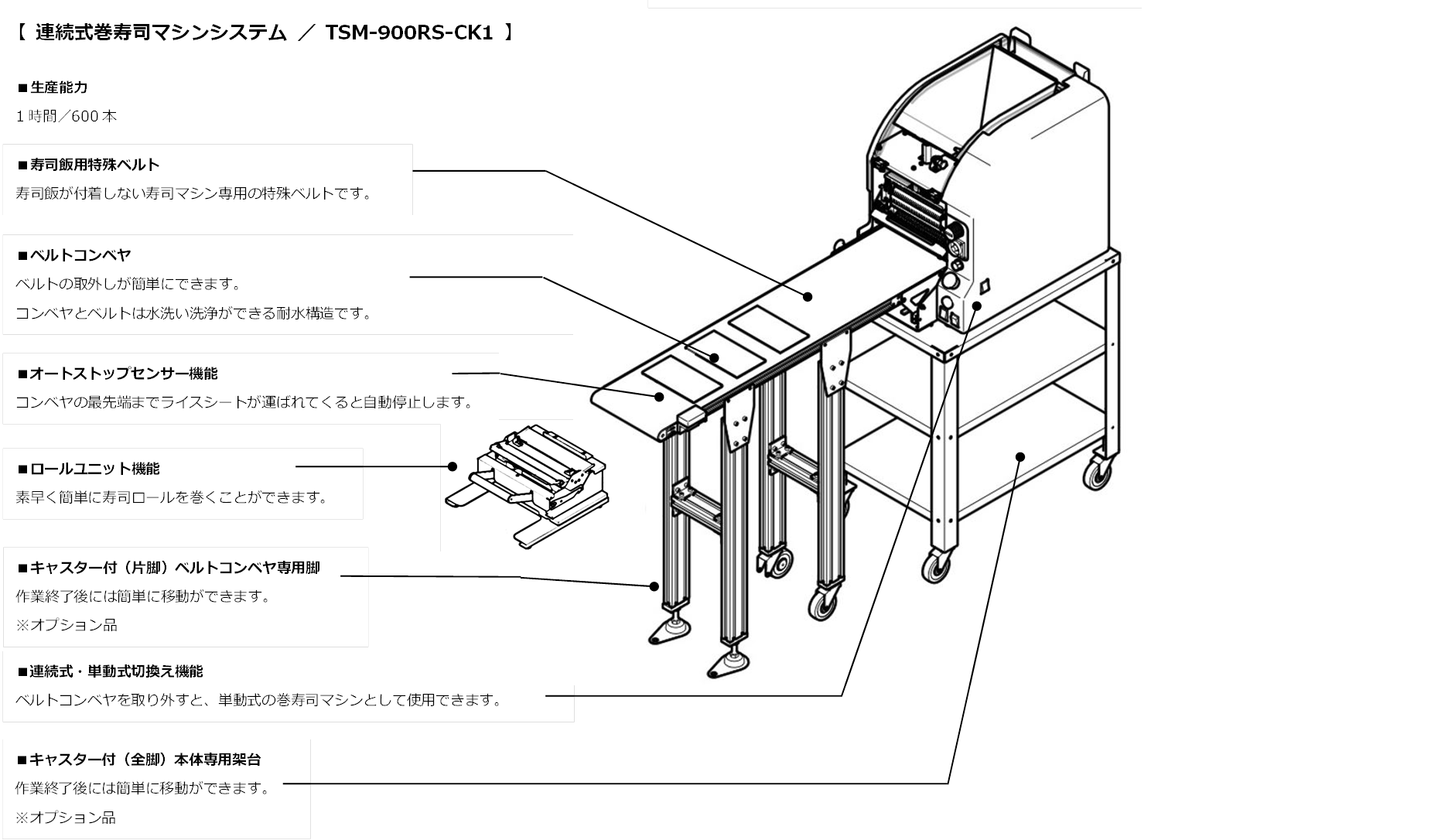

寿司ファクトリー向け連続式巻寿司システム。1時間600本の生産に対応できる拡張コンベヤシステム。

海外規格対応:

UL/NSF,CSA,CE

寿司ファクトリー向け高速生産コンベヤシステム

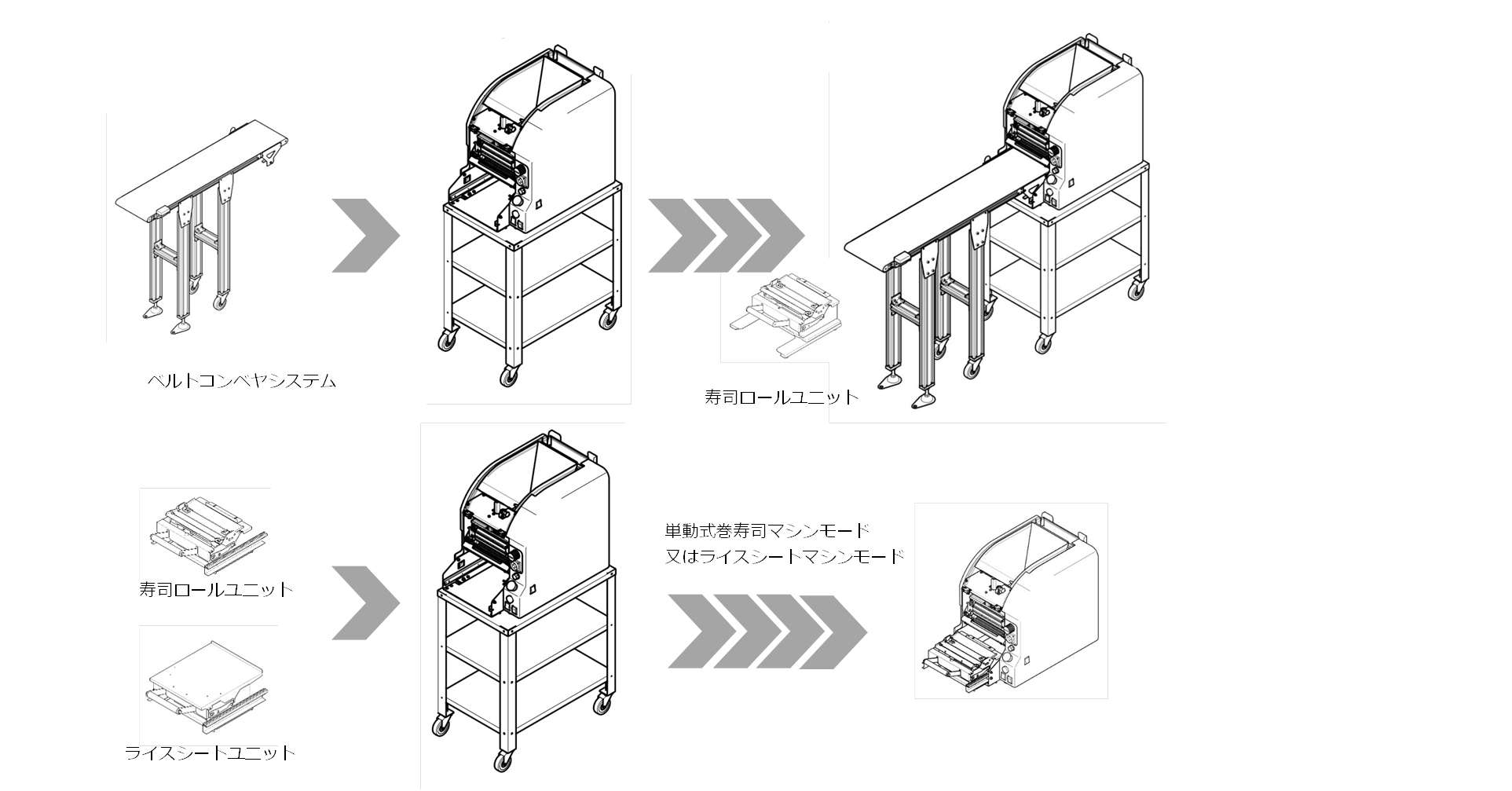

運転モード切換え機能(単動⇔連動)

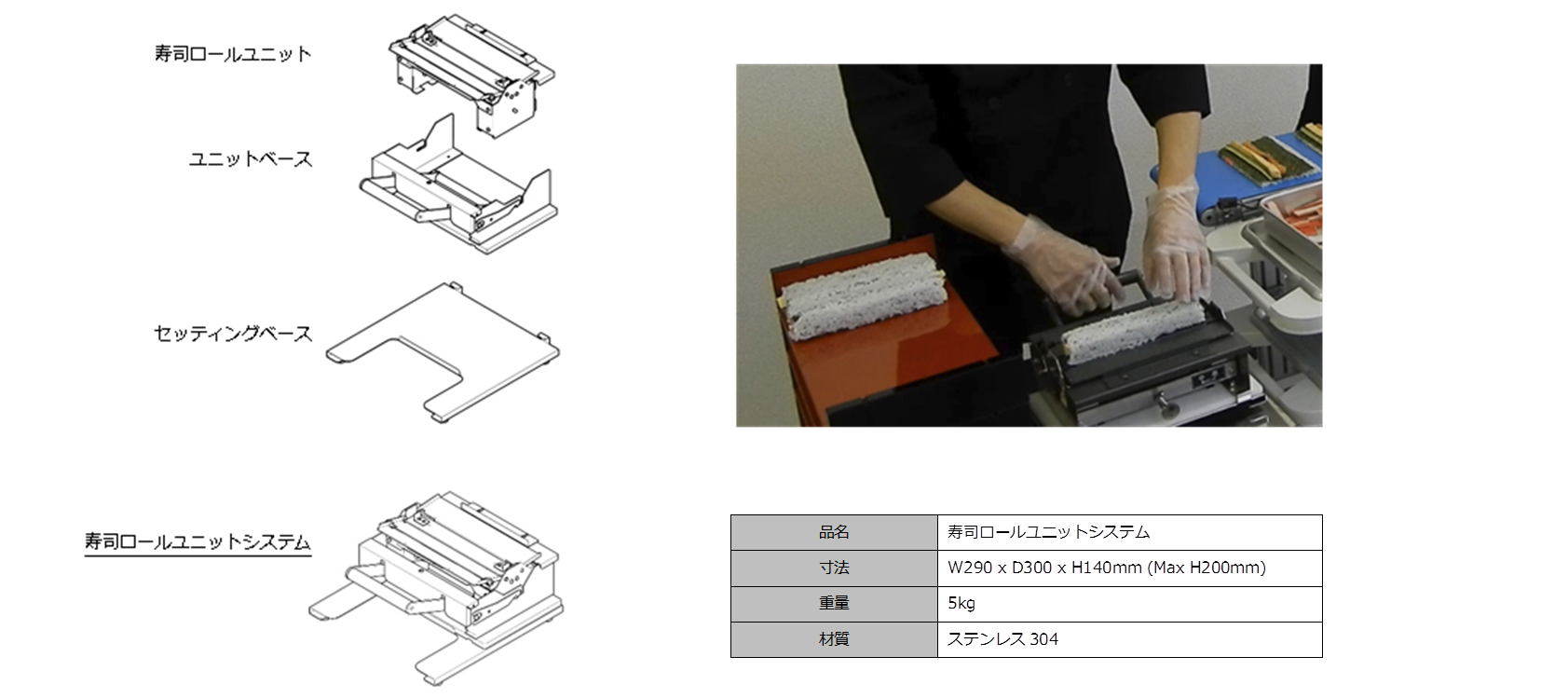

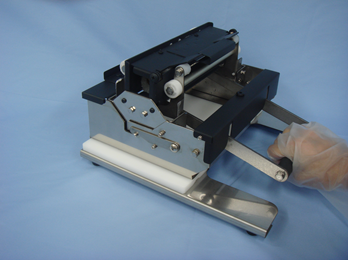

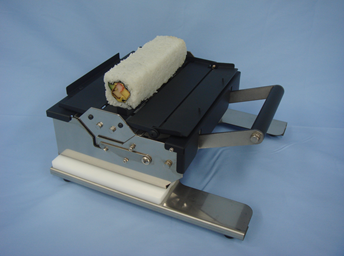

寿司ロールユニットシステム

寿司職人がつくるクオリティーの高い巻寿司づくりを素人のスタッフがかんたんに再現できるロール機能

巻寿司をつくったことがない素人のスタッフが、ウラ巻や海苔巻をかんたんに効率良くきれいに巻くことができます。

海苔を外側に巻く海苔巻・海苔を中に入れて巻くウラ巻はもちろん、スパイラル状に巻くウラ巻も簡単に巻くことができます。

崩れやすいウラ巻の場合には、寿司職人と同じようにしっかりと巻くための巻き直しを素人のスタッフが簡単に行うことができます。

食材を多く入れるロールメニューでも失敗のロスが無く、素人のスタッフがきれいに巻くことができます。

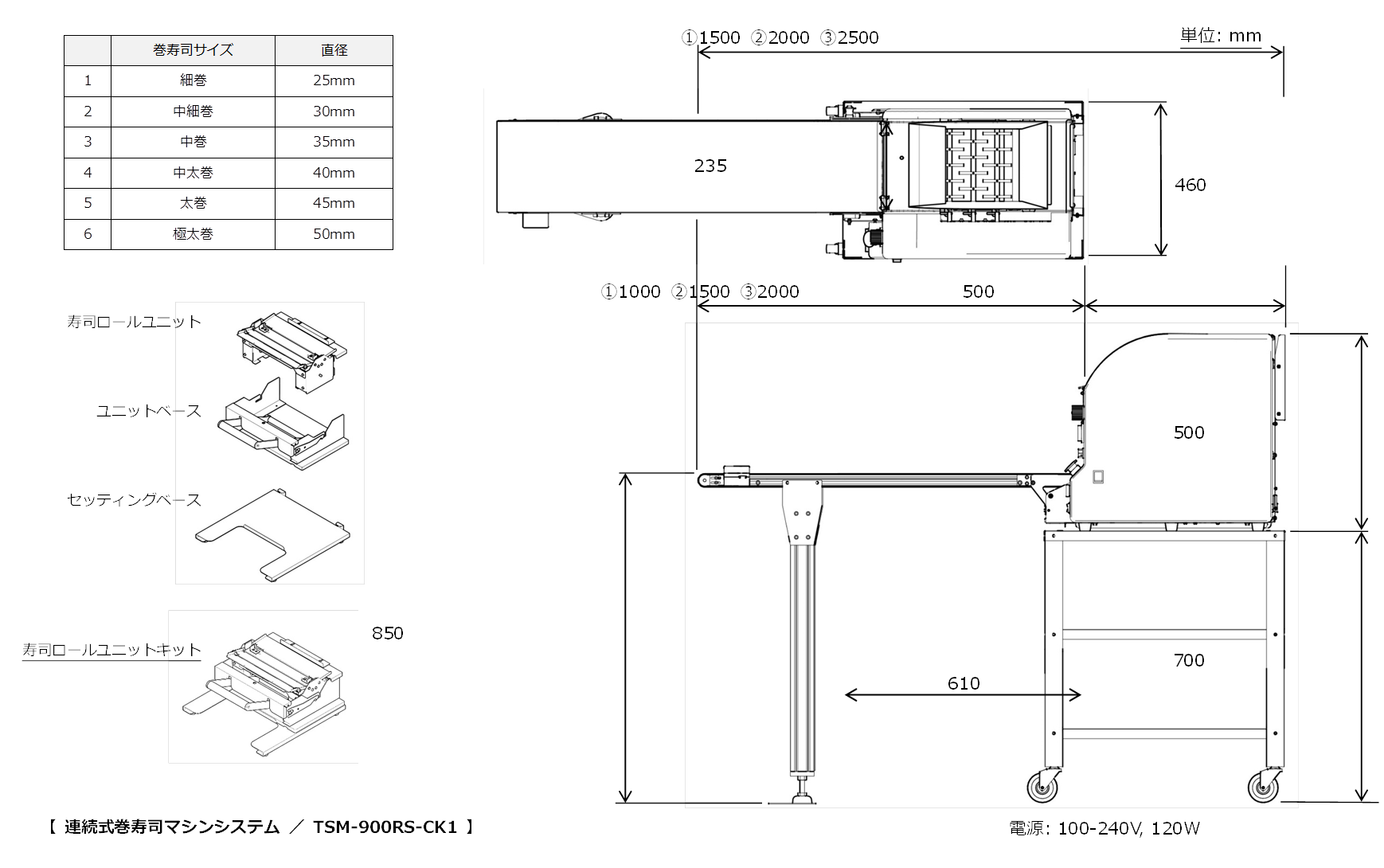

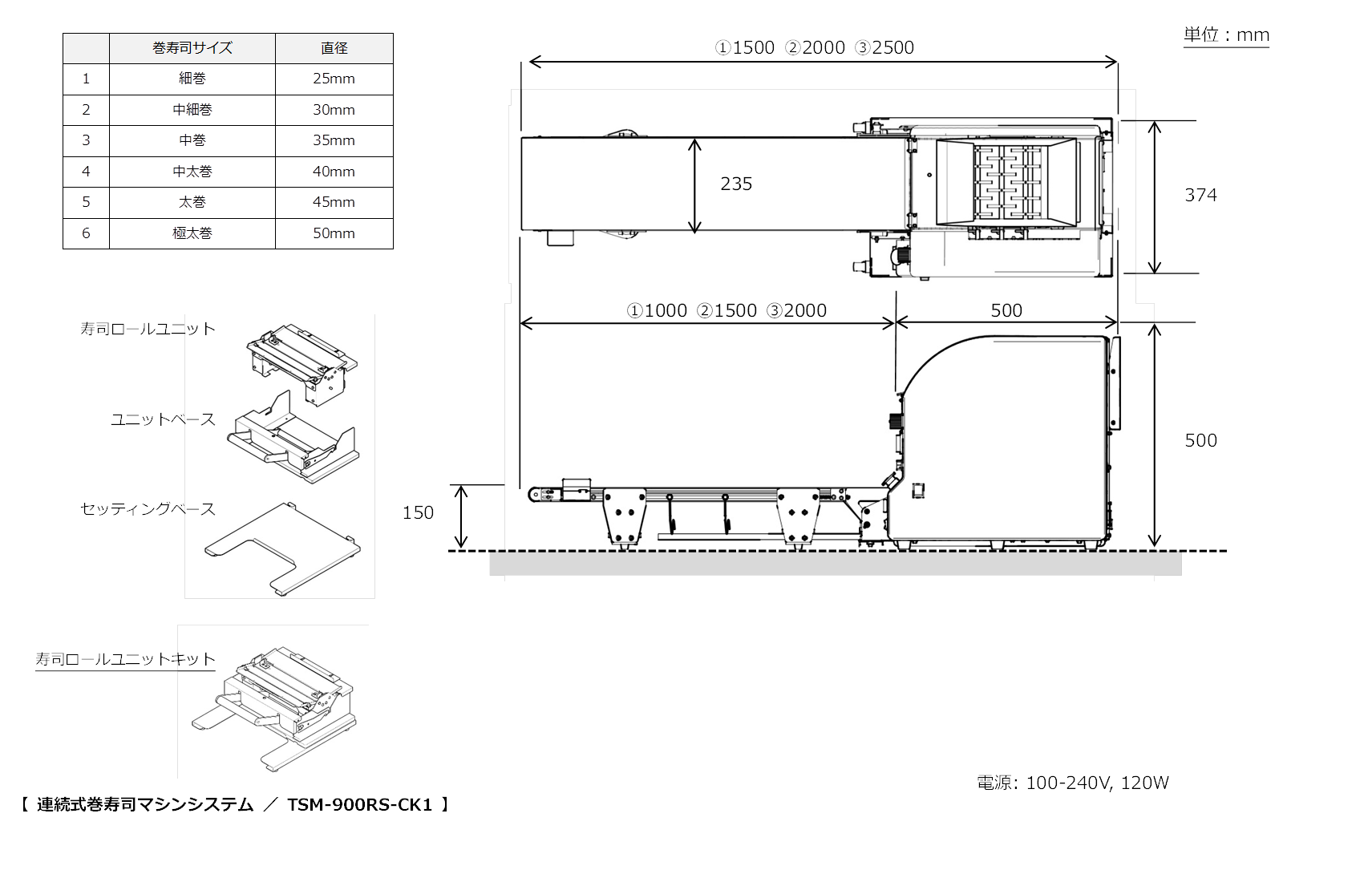

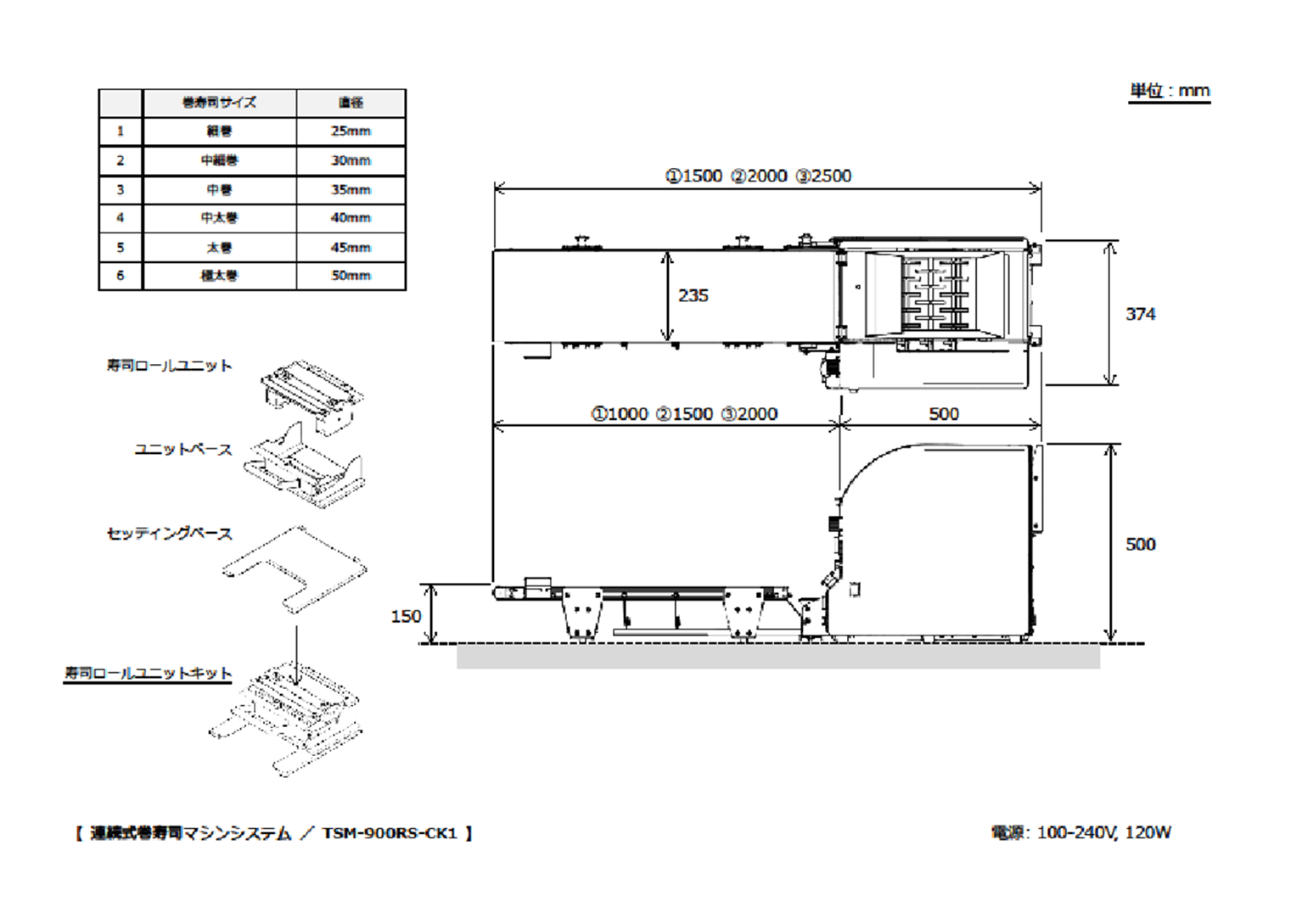

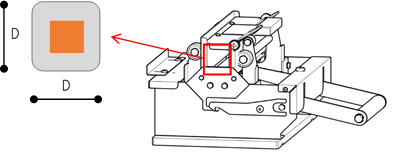

さまざまなロールサイズに対応できるラインナップ

ロールユニットを取り換えることで6種類のサイズの巻寿司がつくれます。

※食材の量や寿司飯の温度により、実際の巻上りの直径はロールユニットサイズより少し大きめになることがあります。

6種類のロールユニットとライスシート用ユニットが有ります。

| サイズ | ロールユニットサイズ(D x D) | グラム設定の目安(1本) | |

| 1 | 細巻 | 25 x 25mm | 80-100g |

| 2 | 中細巻 | 30 x 30mm | 100-130g |

| 3 | 中巻 | 35 x 35mm | 130-150g |

| 4 | 中太巻 | 40 x 40mm | 150-200g |

| 5 | 太巻 | 45 x 45mm | 200-250g |

| 6 | 極太巻 | 50 x 50mm | 250-300g |

| 7 | ライスシート | - | 80-300g |

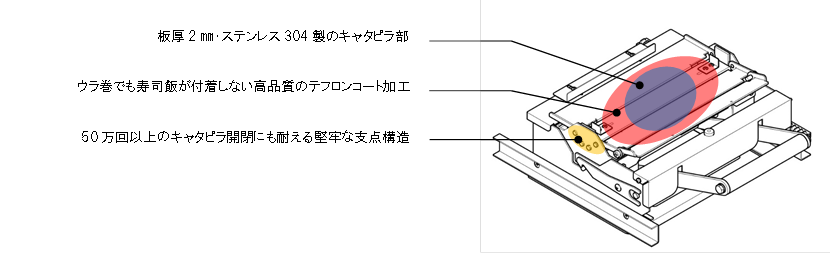

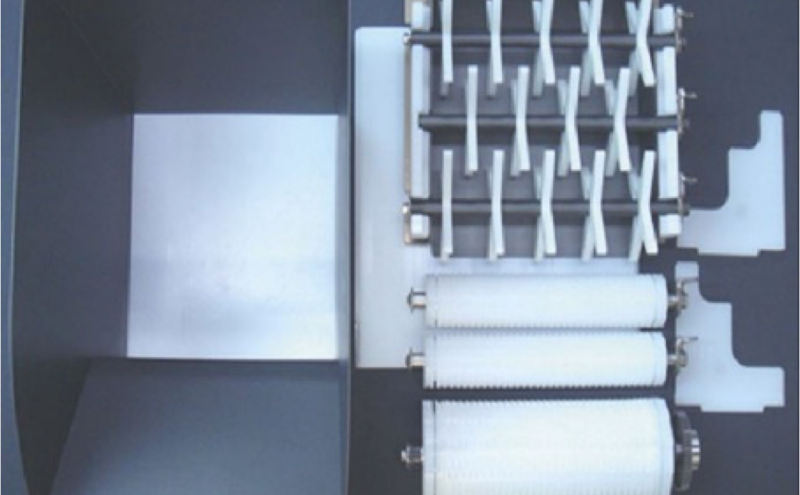

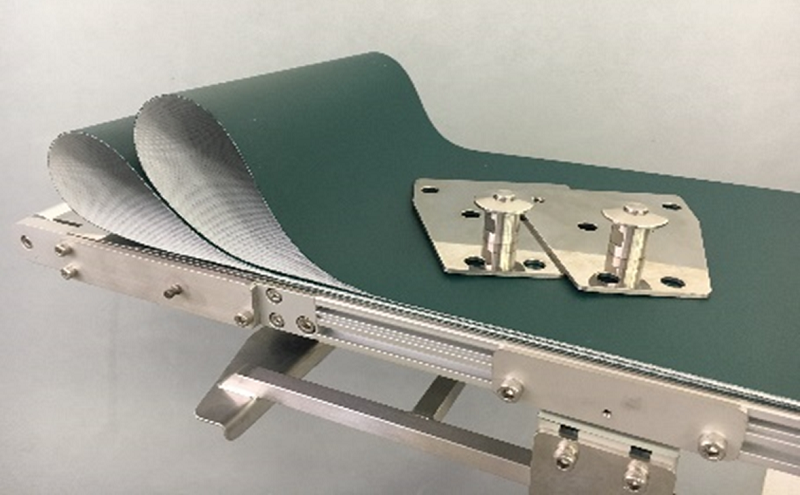

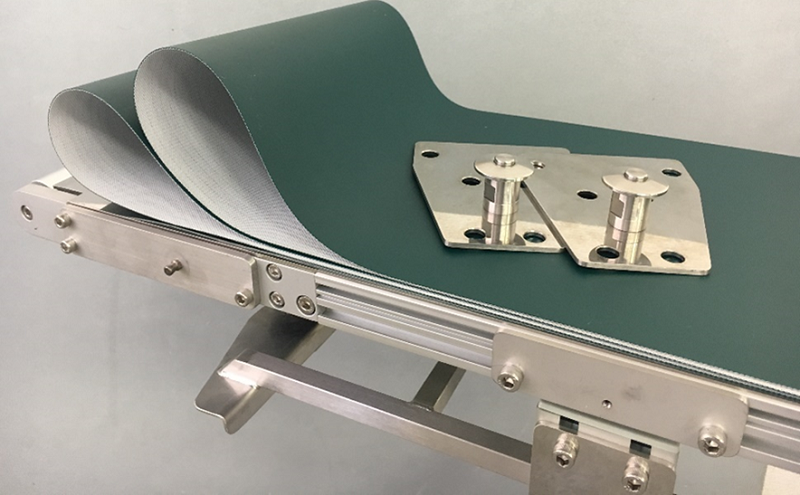

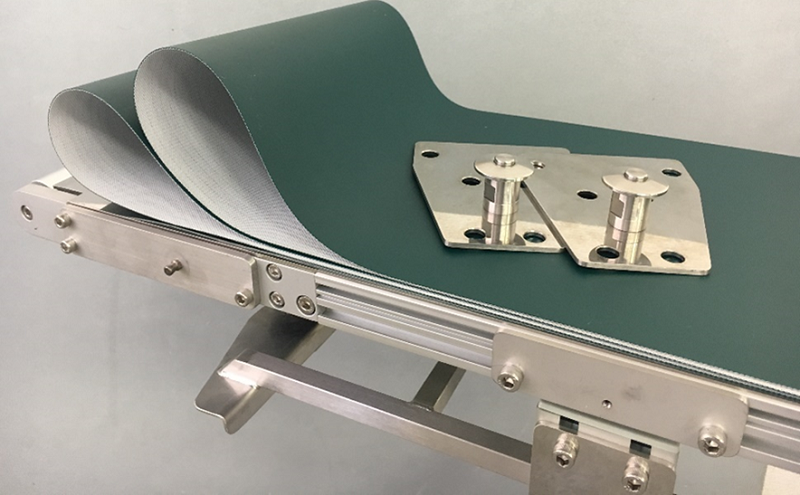

剛性が高く堅牢で高寿命

稼働頻度が最も高いロールユニットのキャタピラ部はステンレス304製で剛性が高い堅牢な構造になっています。ロールユニットのキャタピラ開閉の支点部は50万回以上の開閉稼働に耐える強度と耐久性があります。ロールユニットには、非粘着・耐熱・耐摩耗・耐薬品性に優れた耐久性が高いハイグレードなジュポン社製テフロンコートを施していますので寿司飯が付着しません。

メンテナンスやトラブルの軽減

ロールユニットのセミオート化によりマシン本体を簡素化し、メンテナンスやトラブルがとても少ないマシンになっています。

高寿命の耐久性

マシン本体とロールユニットはシンプルで壊れにくく、8年間以上使用できる耐久性があります。

キャスター付き移動対応モデル

据置型デスクトップモデル

操作性・洗浄性

1時間600本分のライスシートがつくれます。

ライスシートが先端まで送られてくると、マシンが自動でストップします。

洗浄部品は60秒で取り外しできます。洗浄は1日1回で衛生的に使えます。

寿司飯が付着しない専用ベルトです。

ベルトは簡単に取外しが可能で、ベルトとコンベヤは水掛洗浄ができます。

耐久性・高寿命

ベルトコンベヤのセンサーは、防水性・耐油性に優れたIP67仕様です。

主要部分の金属はステンレス304製で、衛生的で耐久性が高く堅牢です。

耐腐食加工を施したアルミ製のフレームは軽量で耐久性が高く堅牢です。

ベルトは耐水性・耐油性が高く、糸ほつれ防止タイプで丈夫です。

キャスターはステンレス304製で、錆に強く高寿命です。

TSM-900RS-CK1での巻き寿司製造工程を動画で解説

製品仕様

- 製品名

- 連続式巻寿司マシンシステム/SUSHI ROLL MACHINE WITH CONTINUOUS SYSTEM

- 型式

- TSM-900RS-CK1

- 仕向国

- TSM-900RS-CK1 TypeA : アメリカ・カナダを含む、その他100-120V地域

TSM-900RS-CK1 TypeB:ヨーロッパ・オセアニア・アジア・南米・中東・ロシアを含む、その他220-240V地域 - 海外規格

- UL/NSF, CSA,CE

- 生産能力

- 連続モード

ライスシートの生産能力:1枚/6秒, 1時間600枚

単動モード

ライスシートの生産能力:1枚/6秒, 1分間2-4本の巻寿司をつくることができます。

*巻寿司に入れる食材のセット時間により生産能力は異なります。 - 本体寸法

- 【巻寿司マシン】

W374 x D600(使用時D800) x H500mm

※巻寿司マシンを専用架台に設置した場合の高さはH1200mmになります。

【ベルトコンベヤ接続時】

コンベヤベルト①1000mmの場合:W374 x D1500 x H500mm

コンベヤベルト②1500mmの場合:W374 x D2000 x H500mm

コンベヤベルト③2000mmの場合:W374 x D2500 x H500mm

※巻寿司マシンを専用架台に設置した場合の高さはH1200mmになります。

【ベルトコンベヤ】

W235 x D1000 x H150mm

※ベルトコンベヤを専用架台に設置した場合の高さはH850mmになります。

【ロールユニットシステム】

W290 x D300 x H140mm(Max200mm) - 本体重量

- 【巻寿司マシン】

42kg

※巻寿司マシンの専用架台は00kgになります。

【ベルトコンベヤ】

コンベヤベルト①1000mmの場合:00kg

コンベヤベルト②1500mmの場合:00kg

コンベヤベルト③2000mmの場合:00kg

※ベルトコンベヤの専用脚付はプラス00kgになります。

【ロールユニットシステム】

5kg - 電源

- TSM-900RS-CK1 TypeA : 100-120V 50/60Hz

TSM-900RS-CK1 TypeB : 220-240V 50/60Hz - 消費電力

- 120W

- 寿司飯容量

- 9kg

- オプション

- ロールユニット:

ロールユニット:

【幅180㎜用】細巻(25㎜)/中細巻(30㎜)/中巻(35㎜)/中太巻(40㎜)/太巻(45㎜)/極太巻(50㎜)/ライスシート専用

【幅200㎜用】細巻(25㎜)/中細巻(30㎜)/中巻(35㎜)/中太巻(40㎜)/太巻(45㎜)/極太巻(50㎜)/ライスシート専用

*( )内の寸法は巻寿司の仕上り直径になります。

ローラーユニット:

【ノーマルタイプ】ライスシート幅180㎜

【ワイドタイプ】ライスシート幅200㎜

【マルチタイプ】ライスシート幅180㎜と200㎜の両方に対応できます。

マニュアルダウンロード

お客様の声

[siteorigin_widget class="WP_Widget_media_post"][/siteorigin_widget]

- Producut Category

- Maki